Why we built MTK: a better SDK for digital manufacturing

Learn how MTK was born from real-world needs in CNC, sheet metal, and molding. Built for engineers building quoting, DFM, and manufacturing platforms.

I still remember writing the first lines of what would later become MTK. It was 2016, in a hotel room in San Diego, California, USA. I was getting ready for a client meeting the next morning and needed a simple prototype to demonstrate feature recognition and billet calculation. That quick demo turned into something much more.

At the time, we were discussing a future custom development project built on top of our CAD Exchanger SDK — a CAD interoperability toolkit that provides APIs to work with B-Rep models, but not a full-blown modeling kernel like Parasolid or Open CASCADE. And as we worked with more and more users, we started seeing a pattern.

Observing the pattern

Many of our customers were trying to solve similar problems:

- Extracting features from imported CAD files

- Running DFM (Design for Manufacturability) checks

- Building cloud-based quoting platforms

- Developing internal web tools to automate manufacturing

Some of them were software vendors building MaaS platforms. Others were manufacturing companies modernizing their quoting workflows. They started with CAD Exchanger SDK — which gave them high-quality STEP import, B-Rep access, and reliable web visualization. But from there, everyone built their own custom stack of geometry logic, heuristics, and rules.

We realized they were all rebuilding the same wheel — with varying levels of success.

From interoperability to manufacturability

That’s when it became clear: the world didn’t just need better CAD viewers or importers. It needed a toolkit designed specifically for manufacturing.

So we built one.

We took everything we had learned — from custom projects, from support requests, from watching our users struggle or succeed — and created a new SDK. We called it MTK: the Manufacturing Toolkit.

It launched quietly in 2021, and for a while, it stayed in the shadow of its older sibling, CAD Exchanger. But now it’s stepping into the spotlight.

Built for developers like us

MTK is designed for software developers building quoting systems, CAM workflows, cloud manufacturing platforms, or any tool where geometry meets production.

We’re developers too — and we’ve been in those shoes. That’s why MTK is lightweight, well-documented, and pragmatic. It’s written in C++ but integrates into Python, C# or Java apps. CAD is tough in itself so we try to lower the learning curve by offering multiple code examples, tutorials and demos.

It’s not based on AI (at least not yet). Everything in MTK is driven by classic computational geometry and heuristics, honed through real-world usage. That means you get full control, predictable behavior, and no surprises in your CNC or sheet metal jobs.

What’s inside

MTK includes support for:

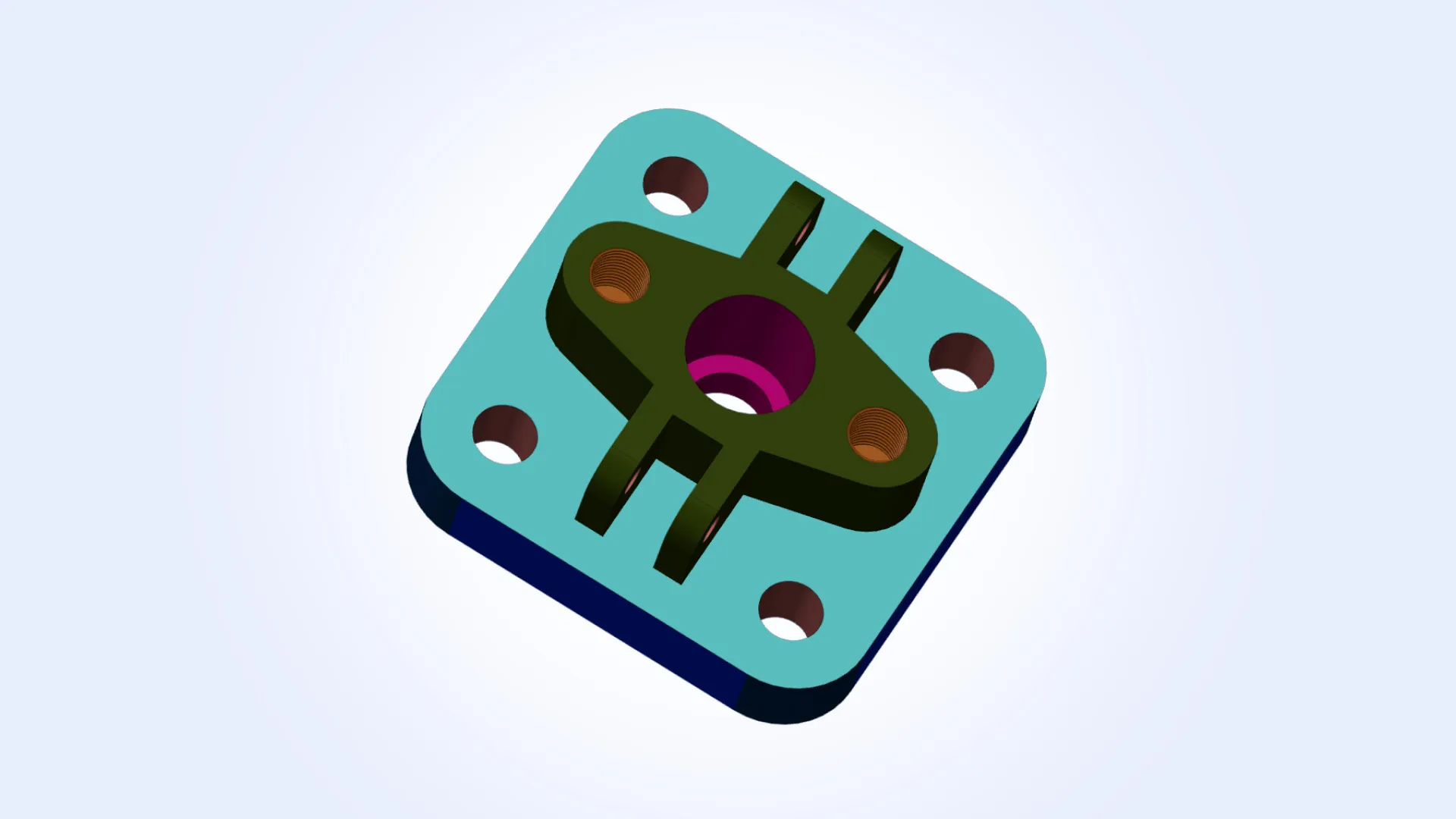

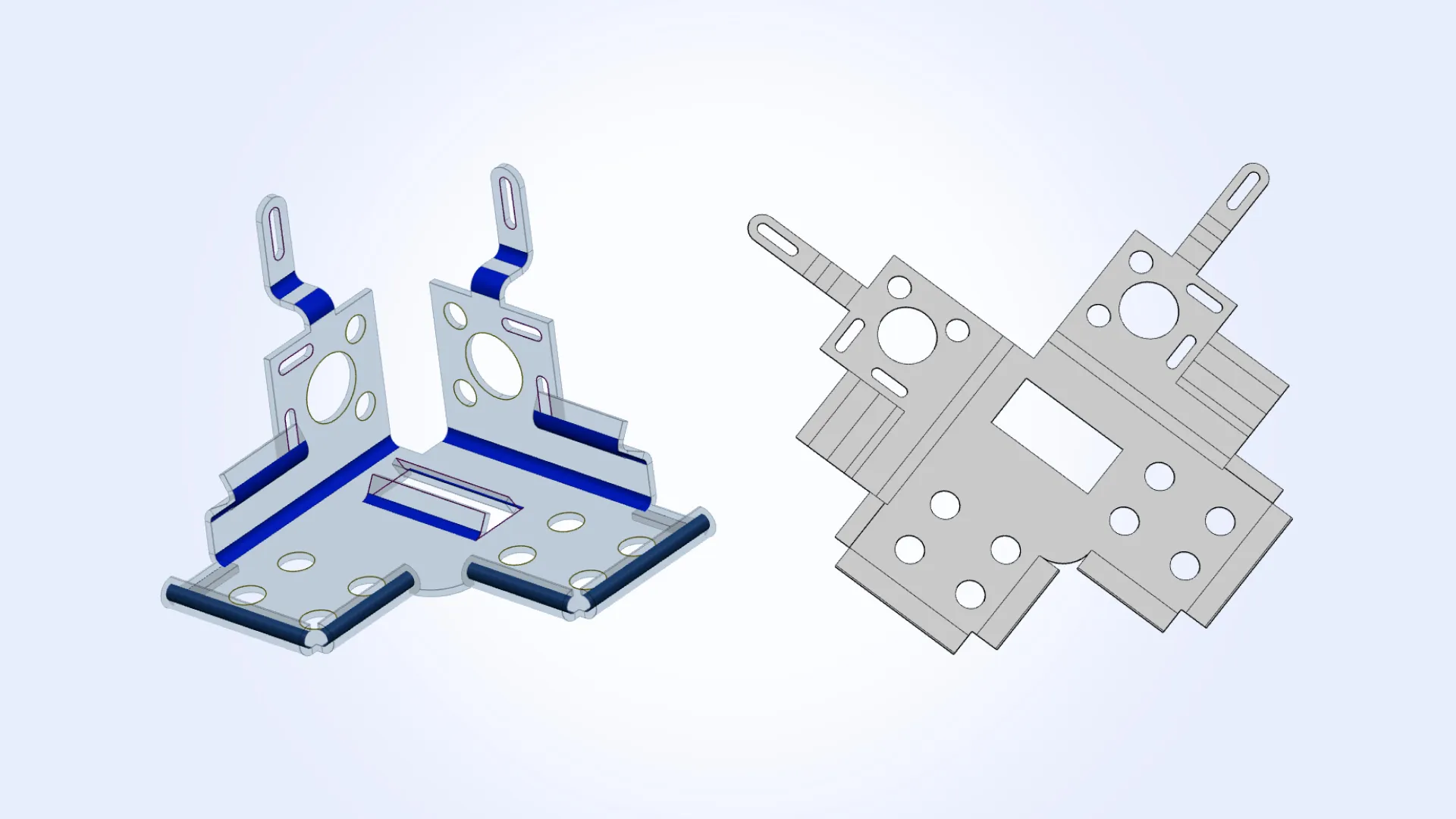

- Feature recognition (machining, sheet metal, molding)

- DFM checks (for the same processes)

- Unfolding (for sheet metal)

- Nesting

- Bounding box, volume, surface area, wall thickness, draft angle and many other computations

- CAD import and web visualization

- And more to come — including additive manufacturing

It’s already helping teams automate cost estimation and quoting, accelerate DFM checks — without reinventing the wheel.

About the name

We spent a long time searching for a fancy name. But in the end, we stuck with MTK — short, technical, and to the point. Like the product itself.

Maybe one day we’ll come up with something more poetic. For now, MTK does the job.

(If something creative crosses your mind, drop me an email)

What’s next?

We’re not trying to be everything to everyone. But if your team is working in manufacturing, and you’ve felt the pain of gluing together half a dozen libraries just to build a working prototype, or got stuck debugging an in-house math algorithm that breaks at every other customer’s STEP file — we’d love to help.

Start with our online demos. Or just reach out — I’d be happy to hear what you’re working on.