How much does a CNC part really cost?

Understand what really drives CNC part pricing - from material and machining time to tolerances, labor, tooling, and markup.

Behind the pricing models for CNC manufacturing

Ask ten engineers how much a part costs - and you’ll get twelve answers.

Not because they’re wrong. But because the question looks simple, and never is. It’s like asking: “How much does an Uber trip cost?” Same route - but time of day, traffic, surge pricing will change the outcome completely.

Now imagine that, but with aluminum, a 5-axis mill, three different operators, and a CMM check at the end.

The “99% accurate” myth

Some platforms claim their CNC pricing is “99% accurate.” It sounds impressive - and reassuring. But is it even possible?

Let’s try a simplified view of production cost:

Cost = Material + Machining time + Labor + Setup + Post-processing + Tooling

Even this basic formula raises big questions:

- What kind of material? Aluminum or titanium?

- What’s included in machining time? Just roughing - or finishing, tool changes, and pauses?

- Whose labor rate? A shop in Ohio, or a plant in Shenzhen?

- Is post-processing just deburring - or heat treatment, anodizing, inspection, packaging?

- How often do tools wear out? Who pays for broken drills and chipped end mills?

Every one of these can swing cost by 2×, 5×, or more - for the same geometry.

And here’s the kicker: Most of that information isn’t even in the STEP file.

And then there’s markup.

Price = Cost + Markup

Markup isn’t arbitrary. It covers:

- company overhead (software, rent, management)

- risk (rejected parts, late deliveries)

- negotiation margin (volume discounts, priority orders)

- and yes, profit

So when a system says “99% accurate,” the question is - accurate compared to what? The average price from one supplier? A guess based on volume? Or a cost model that doesn’t account for half the variables?

Real pricing isn’t about predicting a single number. It’s about understanding where that number comes from - and how each factor contributes.

Let’s walk through those factors, one by one.

What actually drives CNC part cost?

At a glance, CNC pricing seems simple: take the material cost, add machining time, and you’re done. But in reality, that’s like estimating construction costs by just looking at the size of a building.

Let’s unpack what actually goes into pricing a CNC part - whether it’s a one-off prototype or a production run of 500 units.

1. Material: more than just price per kilogram

Material affects part cost in three major ways:

1. Raw material price

Different materials have vastly different base costs:

Material Approx. cost (USD/kg) --------------- --------------------- Aluminum 6061-T6 $3.5–$4.5 Mild steel (A36) $1.0–$1.5 Stainless 304 $4.5–$6.0 Titanium Grade 5 $25–$35

Same geometry - up to 10× difference in base cost

2. Machinability

Some materials are slow to cut, eat tools, or require coolant and specialized inserts:

- Aluminum is fast, forgiving, and cheap to machine.

- Stainless requires slower feeds, more rigidity, and burns through tools.

- Titanium is notoriously tough: low cutting speed, high tool wear, and thermal issues.

Worse machinability = longer cycle times + more expensive tooling

3. Post-processing and handling

Some materials require extra steps after machining:

- Titanium parts often need stress relief or heat treatment.

- Stainless may require passivation or protective cleaning.

- Plastics may warp or deform during handling and need special packaging.

Material isn’t just a line item. It impacts every downstream step: from cycle time and tool life to finishing and QA.

2. Geometry and setup effort

Geometry defines how complex the part is - but complexity isn’t just about shape. It’s about how long it takes to program and set up the job.

- CAM programming: A part with simple 2.5D features might take 10–15 minutes to program. A part with 3D surfacing, deep pockets, or multiple setups can take several hours - especially if fixtures need to be modeled. CAM time is labor-intensive and often billed separately at hourly rates that depend on location and team.

- Setup time: Includes mounting the stock, aligning coordinate systems, zeroing tools, checking fixtures. Even for a small part, this can take 30–60 minutes of machine downtime, depending on the complexity. Some shops amortize this cost over the batch; others charge a fixed setup fee.

- Tool changes: Switching tools between operations adds time, especially on machines without automatic changers.

Even before the spindle starts cutting, real cost has already accumulated.

3. Machining time - not just cutting

When people say “machining time,” they often mean “spindle time.” But in reality, it’s more than that.

Machining time includes:

- Toolpath execution - actual material removal

- Rapid moves and repositioning - non-cutting movements

- Tool changes - automatic or manual

- Chip evacuation and air blasts

- Coolant activation and delays

- Spindle ramp-up, braking, feed hold, and cycle pauses

Even for a simple part, these add up. For more complex geometry - deep pockets, multi-axis reach, microfeatures - the impact is exponential:

- A simple Ø10 mm hole can be drilled in 30 seconds.

- A 50 mm deep pocket may take 5–10 minutes depending on the tool, step-downs, and feed rate.

- Thin-walled features require more passes and slower feeds to avoid chatter or part failure.

This time is then multiplied by the machine hourly rate, which varies by region and machine class.

Some approximate location-specific rates (machine and labor cost):

Region Machine hourly rate Labor rate --------- ------------------- ----------- USA $80–$120/hr $20–$50/hr Germany $75–$150/hr $25–$60/hr China $25–$45/hr $5–$15/hr

Same geometry, 3–5× difference in cost based on location alone

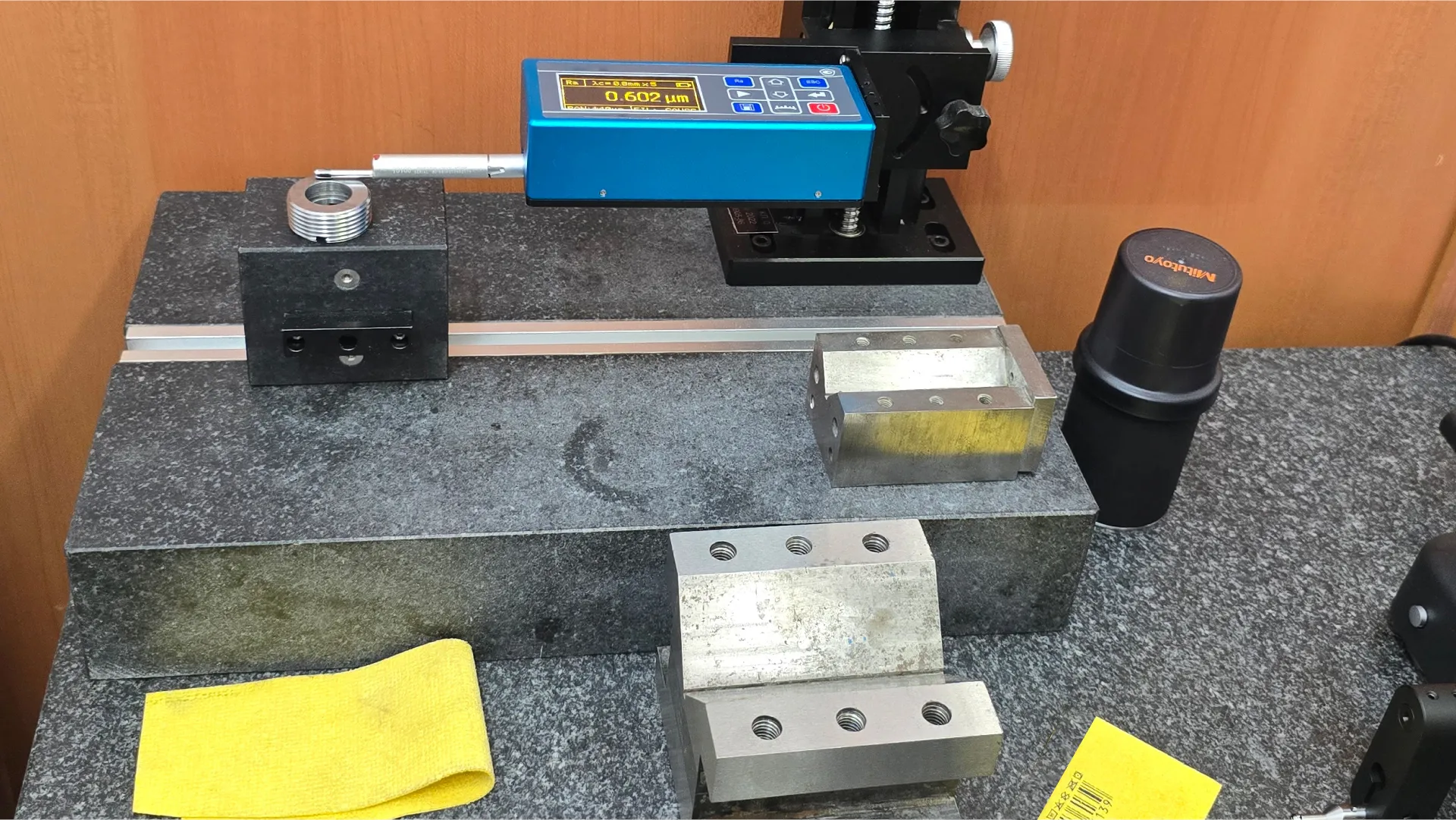

Tolerances matter

Tight tolerances don’t just increase QA time - they increase cycle time directly:

- A flat face with ±0.2 mm tolerance may need just one roughing pass

- The same face with ±0.02 mm will likely need semi-finishing, finishing, and post-machining inspection.

- Holes with ±0.01 mm typically require boring and reaming.

- Any tolerance below 0.01 mm often implies additional inspection - CMM, or manual gauge.

Tighter tolerances can increase machining time by 5–20× per feature - and drive up QA costs as well. The difference between “machined” and “precision-machined” isn’t just semantics - it’s minutes per feature, and dollars per part.

Tool wear and cost

Tooling isn’t just background noise - it’s a real cost driver. Harder materials, tighter tolerances, and high removal volumes all lead to more wear, breakage, and replacement.

- A carbide end mill might last 50 parts in aluminum - but just 10–15 in stainless

- Micro drills (Ø1 mm) may cost $15–30 and break on a bad chip

- Complex parts with many tool changes increase both tool inventory and setup time

Some shops estimate tooling cost as a flat rate per part. Others use a percentage of machining cost (e.g. 5–10%). Either way, the more you cut - and the harder the material - the more tooling you burn.

4. Labor rate - not just machines

Machining is only part of the picture. People cost money too:

- Operator time: Loading/unloading parts, verifying first articles, monitoring jobs, and manual deburring.

- Quality inspection: Checking tolerances, especially if tight specs are involved (e.g. ±0.01 mm).

- Logistics and admin: Packaging, labeling, paperwork.

And that time adds up - especially for small batches that require extra attention. (See the table above for labor costs per different regions)

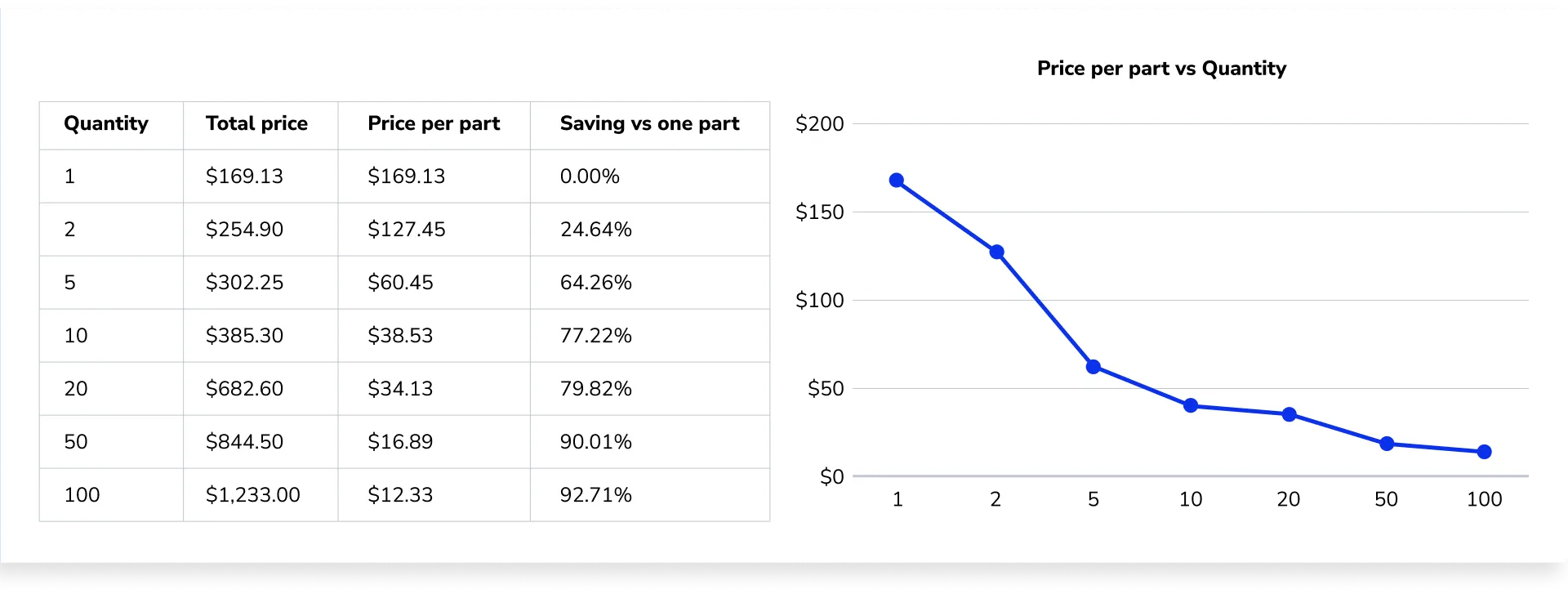

5. Quantity and amortized costs

Here’s where things get interesting.

Some costs are fixed per job, no matter how many parts you make:

- CAM programming

- Setup and fixturing

- First-article inspection

- Custom tooling (if needed)

Other costs are per part:

- Raw material

- Machine time

- Operator handling

- Post-processing (e.g. deburring, anodizing)

Example:

- Setup takes 1 hour at $100/hr - $100

- CAM takes 2 hours at $60/hr - $120

- Total = $220

- For 1 part - $220 overhead

- For 10 parts - $22 per part

- For 100 parts - $2.20 per part

That’s why prototypes cost disproportionately more - they carry 100% of the one-time cost. And that’s why a good pricing model must account for batch size.

6. Pre- and post-processing: invisible but costly

Post-processing may often add $20–$50 or more per part (again this will swing depending on the geography), depending on spec and quality demands:

- Heat treatment: $5–15

- Surface finishing (e.g. anodizing, bead blasting): $3–10

- Deburring (manual): $2–5

- Cleaning and degreasing: $1–3

- Dimensional inspection (CMM): $5–20

- Packaging, labeling, traceability: $2–5

And while some of these costs are per part, others are batch-level (e.g. oven setup, fixture prep). If your pricing model skips these - you’re underestimating total cost.

What MTK provides in this model

MTK doesn’t try to guess your final price. It gives you clean, structured, and relevant geometry intelligence - so you can build pricing models that reflect reality, not just volume and surface area.

Here’s how MTK helps:

1. Billet estimation

MTK estimates the required billet size using:

- Precise bounding box (plus clearance)

- Orientation and symmetry

Great for calculating stock cost and removable volume. Coming soon: support for cylindrical, tubular, and custom billet shapes (e.g., bar stock or pipe)

2. Volume-based material calculation

MTK returns accurate part volume in mm³ - that’s it. You apply density and price logic:

- Want to know mass? Multiply by material density

- Want cost? Multiply mass × $/kg

- Want machine time? (Stock volume - part volume) / material removal rate.

This keeps the system flexible and easy to integrate.

Example: 280 cm³ part × 2.7 g/cm³ (aluminum) - 756 g

- at $4.5/kg = ~$3.40 material

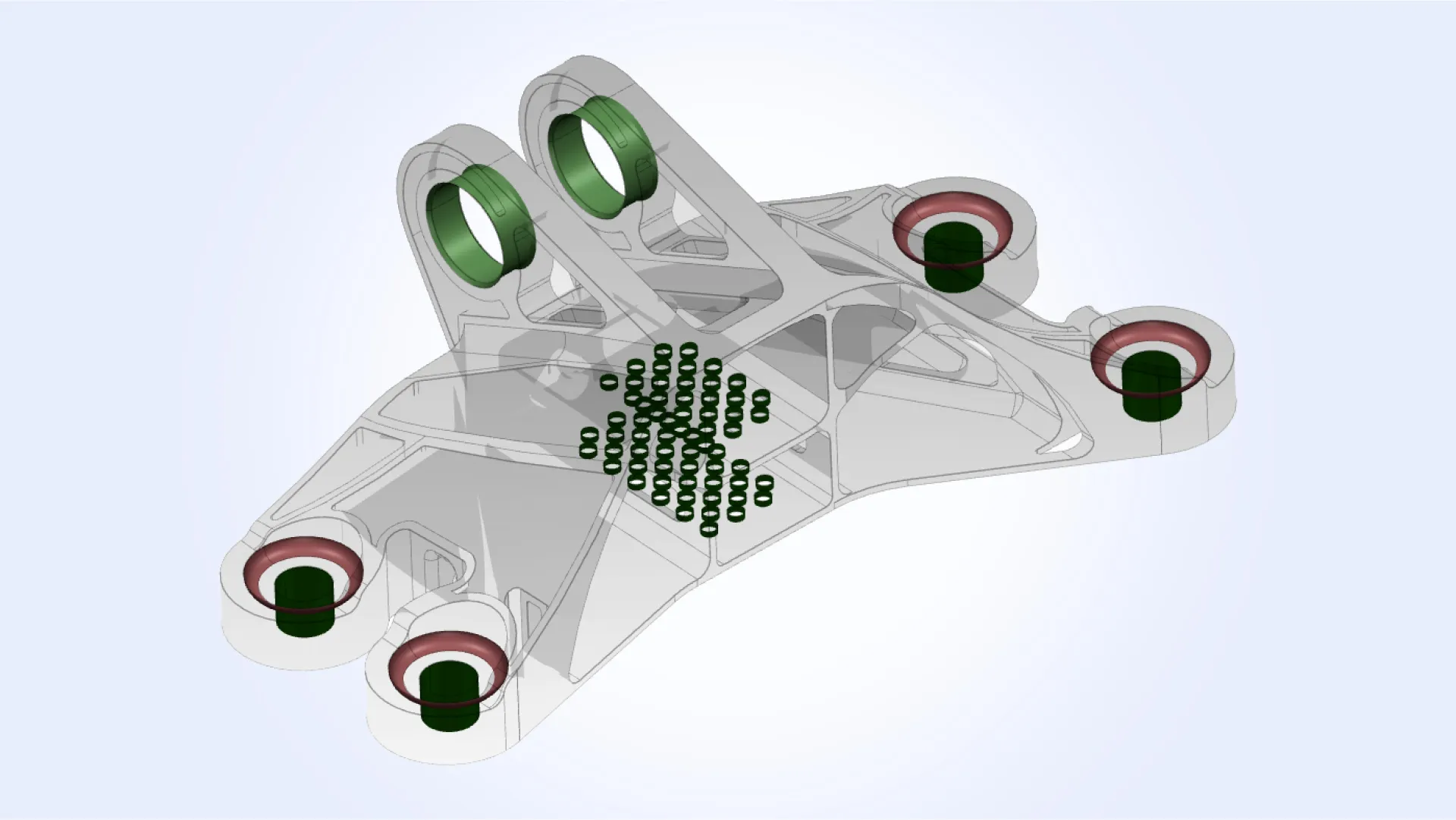

3. Feature-based machining insight

MTK recognizes machining features:

- Pockets, holes, bosses, undercuts, slots, threads

- Tags depth, reachability

- Computes total removable volume

You can map each feature to estimated machining time using internal logic, tool libraries, or ML models. From geometry to structured process steps.

4. DFM analysis for risk and reject rate

MTK flags:

- Thin walls

- Deep narrow pockets

- Sharp transitions

- Complex undercuts

- many other issues

You can use this to:

- Penalize difficult features

- Apply reject-rate modifiers

- Adjust pricing for quality-critical customers

Adds engineering context to commercial estimates.

5. API-driven, configurable, transparent

No black box. You call MTK for what you need: geometry, volume, features, DFM flags - and plug it into your own pricing logic. You add support for:

- Custom materials and densities

- Internal pricing tables

- Post-processing rules

- Region-specific rates

MTK is not a quoting engine. It’s the geometry layer inside your quoting system - from CAD import to feature recognition, and even visual explanation via our built-in web viewer.

Conclusion: it’s not about precision - it’s about insight

In CNC manufacturing, price is never just a number. It’s the result of geometry, material, labor, risk, and process decisions - all filtered through real-world constraints.

There will always be uncertainty. But the more you understand the structure behind a price, the more predictable and scalable your quoting becomes.

That’s where MTK fits in:

- It doesn’t try to compete with ERP.

- It doesn’t claim “99% accuracy.”

- It gives you clean, explainable geometric data - so your pricing model can actually reflect how manufacturing works.

Want to see how it works?

Contact us to get added to a wait list for our new CNC pricing demo, or get in touch to talk through your use case.