Partsimony is changing the game in hardware manufacturing with Manufacturing Toolkit and CAD Exchanger SDK

Discover how Partsimony’s collaboration with CADEXSOFT has made a significant impact, enabling real-time DFM feedback, enhanced supplier engagement, and seamless CAD integration.

Company overview

Partsimony is a software platform that helps hardware companies and manufacturers worldwide meet and smoothly move together from design to production. With a focus on reducing time, cost, and frustration, Partsimony connects design teams within hardware companies with manufacturers to streamline the complex transition of bringing hardware products to market.

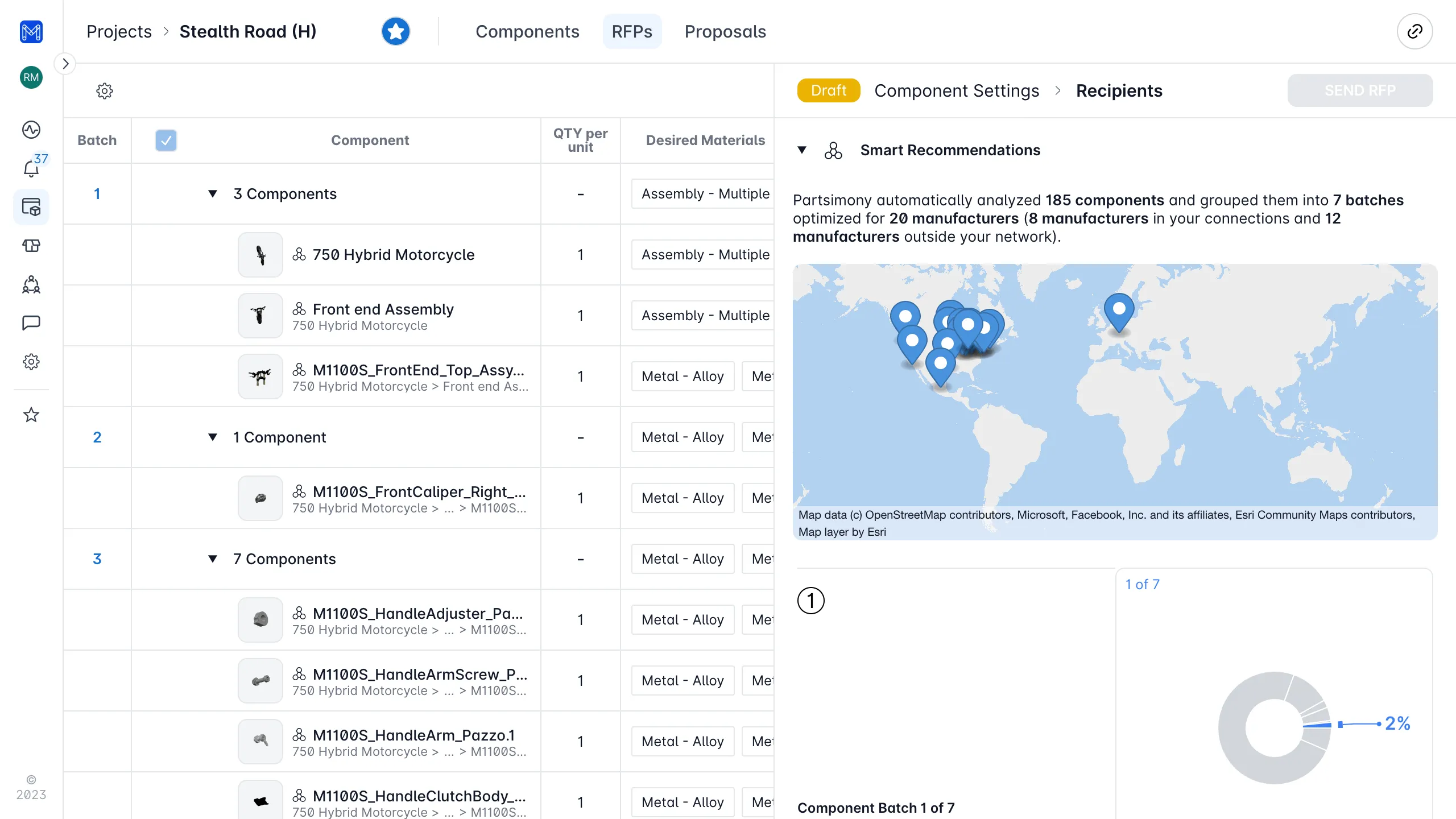

The platform works by analyzing a company’s bill of materials (i.e., 3D CAD files), matching the most suitable suppliers for each component.

Beyond just finding the right suppliers, Partsimony facilitates seamless transactions and provides comprehensive real-time order tracking. This gives hardware companies complete visibility into their supply chain, enabling them to monitor order status, track shipments, and anticipate potential delays. This level of transparency and control empowers businesses to make informed decisions and reduce risks to a minimum.

From 3D printing and machining to injection molding, electronics, castings, and assemblies, Partsimony helps hardware companies save time on supplier searches and dedicate more time to innovation in product development and design.

In turn, manufacturers gain the following benefits:

- Enhanced optimization

Partsimony’s data-driven recommendations help Original Equipment Manufacturers (OEMs) fine-tune design processes, streamline order logistics, and optimize workflows, making production cycles more efficient and cost-effective.

- Strategic decision-making

With real-time insights into supply chain networks, Original Equipment Manufacturers (OEMs) can make informed decisions about partnerships and resources, aligning their capabilities with business goals and maximizing production potential.

- Improved collaboration

A centralized communication hub links all supply chain activities, enabling seamless coordination with clients and suppliers, which reduces miscommunication and builds stronger, more transparent relationships.

“Manufacturing Toolkit helps us optimize designs early, saving time and costs. It provides precise and instant Design for Manufacturability (DFM) feedback focused on key processes, such as sheet metal fabrication and CNC machining. Excellent documentation and support make CADEXSOFT a reliable partner for our needs.”

Roland Mokuolu

Co-founder and COO, Partsimony

Challenges

As Partsimony’s platform evolved, their team faced a challenge: inefficiencies in the design-to-production process. Engineers often created designs that weren’t optimized for manufacturing, leading to costly revisions.

Another challenge arose with the management of multiple 3D CAD formats. Initially, they considered building their own CAD processor but realized it would require too many resources.

Lack of accurate and instant DFM feedback

One of the critical challenges was the inability to provide hardware companies with instant and precise design for manufacturability (DFM) feedback. Developing accurate DFM feedback algorithms proved to be a complex task. Without reliable DFM analysis, Original Equipment Manufacturers (OEMs) risked delays and costly redesigns as issues were only discovered after production began, leading to inefficiencies in the supply chain.

Difficulty in reading multiple 3D CAD formats

Partsimony’s users work in various design programs and have models in different formats, such as SOLIDWORKS, Autodesk Inventor, STEP, and others. To create a streamlined solution, the company needed a tool capable of reading multiple CAD formats and accurately extracting the necessary metadata from them.

Solution

To overcome these challenges, Partsimony chose Manufacturing Toolkit and CAD Exchanger SDK, transforming how the company managed provided DFM feedback and 3D CAD files.

Integration of Manufacturing Toolkit

For manufacturability insights, Manufacturing Toolkit empowered Partsimony to provide robust, early-stage DFM feedback tailored to processes such as CNC and sheet metal fabrication. By integrating the Manufacturing Toolkit into its platform, Partsimony enabled users to receive optimized recommendations directly in the interface, allowing manufacturers to identify potential production issues in the design phase rather than on the shop floor.

CADEXSOFT’s documentation and support offered remarkable flexibility, which further strengthened the integration. This allowed Partsimony to fine-tune solutions tailored to unique client needs and also to adapt quickly to new challenges. As a result, the company achieved lasting improvements in design efficiency and manufacturing cost reduction.

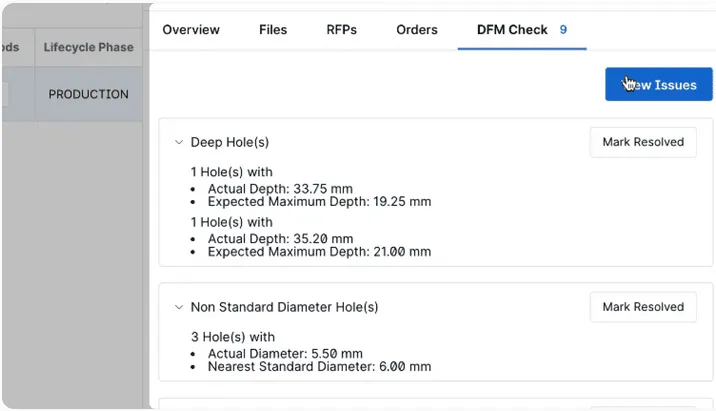

Now, Partsimony platform users can take advantage of comprehensive DFM checks, including:

Suggesting detailed adjustments

It is possible to upload models and inspect the assembly hierarchy to identify components with potential issues. The Manufacturing Toolkit highlights inefficiencies with numerical values and suggested adjustments, making problem areas clear and actionable. Using the “View Issues” option in the DFM Check tab provides insights to help teams enhance manufacturability while reducing costs and complexity.

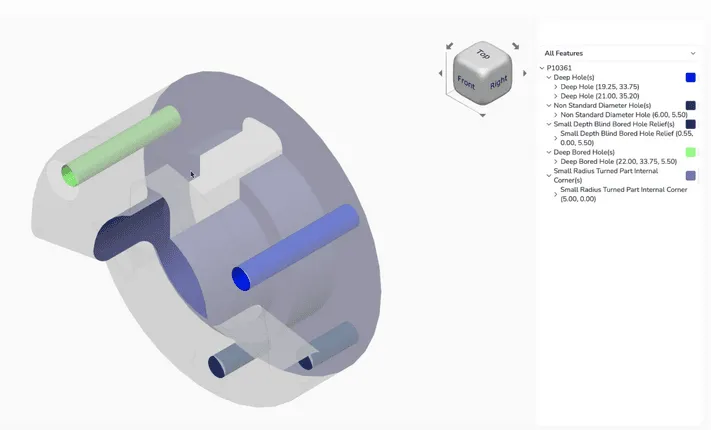

Visualizing DFM results in a smooth 3D

Users can view recommended adjustments directly on 3D models with intuitive visual feedback: it is possible to freely rotate and zoom in on models to refine the DFM analysis results for even the smallest components. Color-coded markers highlight problem areas, enabling teams to quickly prioritize fixes and streamline design improvements for better manufacturability. The platform ensures instant feedback and uninterrupted performance, even when working with complex models, allowing for a seamless UX.

Integration of CAD Exchanger SDK

CAD Exchanger SDK allowed Partsimony users to upload 3D models in over 30 different CAD formats, such as SOLIDWORKS, STEP, and CATIA. It enabled the platform to accurately interpret and extract metadata across 3D CAD systems, creating a unified, consistent dataset without the need to develop separate converters for each file type. This not only saved time but also allowed Partsimony’s hardware clients to manage and share designs without compatibility issues, ensuring smoother workflows and reducing time spent on file conversion and data extraction.

Another standout benefit of CAD Exchanger SDK is its ability to seamlessly integrate into existing software solutions, allowing Partsimony to maintain a cohesive UX. CAD Exchanger’s powerful features were incorporated directly into its own user interface, providing a seamless and user-friendly interface and smooth UX.

This integration eliminated the disjointed experience associated with using separate CAD processing tools, where users might have to switch between different platforms. It also increased security and control over sensitive data, as it removes reliance on third-party cloud services.

Resulting value

The collaboration with CADEXSOFT has allowed Partsimony to significantly enhance its product, streamlining complex processes and optimizing costs in ways that directly impact the end user. The “plug-and-play” efficiency has allowed Partsimony to quickly integrate Manufacturing Toolkit and CAD Exchanger SDK into its own stack, providing a smooth UX.

The CADEXSOFT team has been exceptionally supportive, providing fast responses, high-quality documentation, and, when necessary, customized solutions. All of this has empowered Partsimony to move rapidly through the development stages and focus on delivering value to clients:

- The Manufacturing Toolkit’s DFM checks have been a game changer for cost savings. Partsimony’s users now have the capability to perform DFM checks early in the design phase, enabling them to identify manufacturability issues before committing to production.

- CAD Exchanger SDK enabled the platform to accurately interpret and extract metadata across various CAD systems, creating a unified, consistent dataset without requiring separate converters for each file type.

With these outcomes, Partsimony has been able to deliver an enhanced product experience, reduced costs, and quicker turnaround times.