STL and DXF support, forming feature recognition in Sheet Metal, updated MTK Web examples in Manufacturing Toolkit 2025.6

Expand your manufacturing workflows with new import/export capabilities, identify forming features like embosses and stamps, and experience smoother interaction with MTK Web examples.

New STL and DXF formats

This release significantly expands your import and export options. We’ve introduced support for the STL format, a cornerstone of 3D printing and mesh-based workflows. You can now import and export both ASCII and binary STL files, with support of multi-part handling (ASCII only).

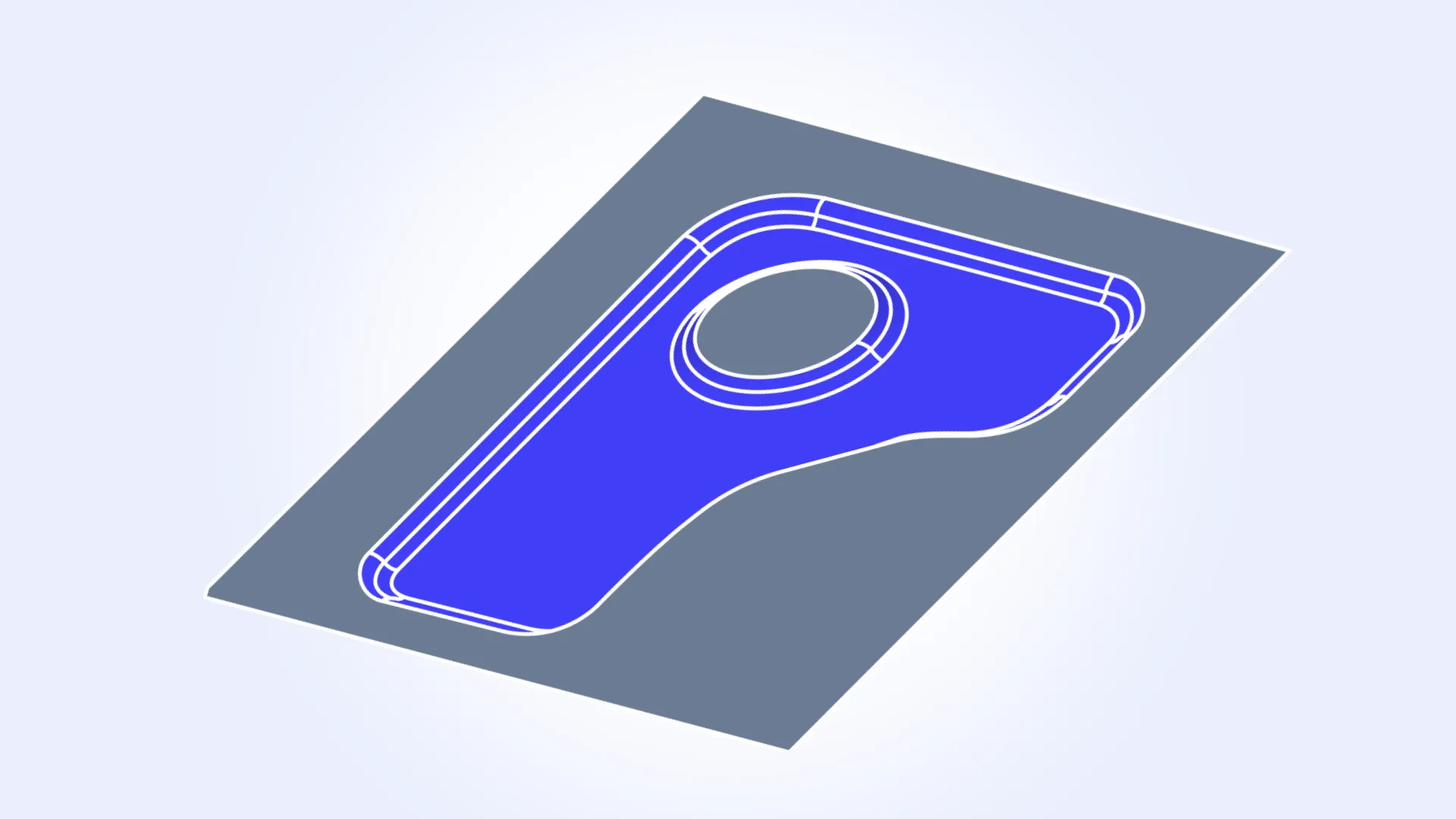

Besides, you can export 2D curve data like unfolded sheet metal models directly to DXF format. These new capabilities bridge the gap between digital design and physical production, enhancing your workflow.

Practical new examples

A new mesh exploration example demonstrates how to work with the newly imported STL mesh data. To help you immediately put theory into practice, we have also extended the Unfolding example to show how to automatically export results to DXF.

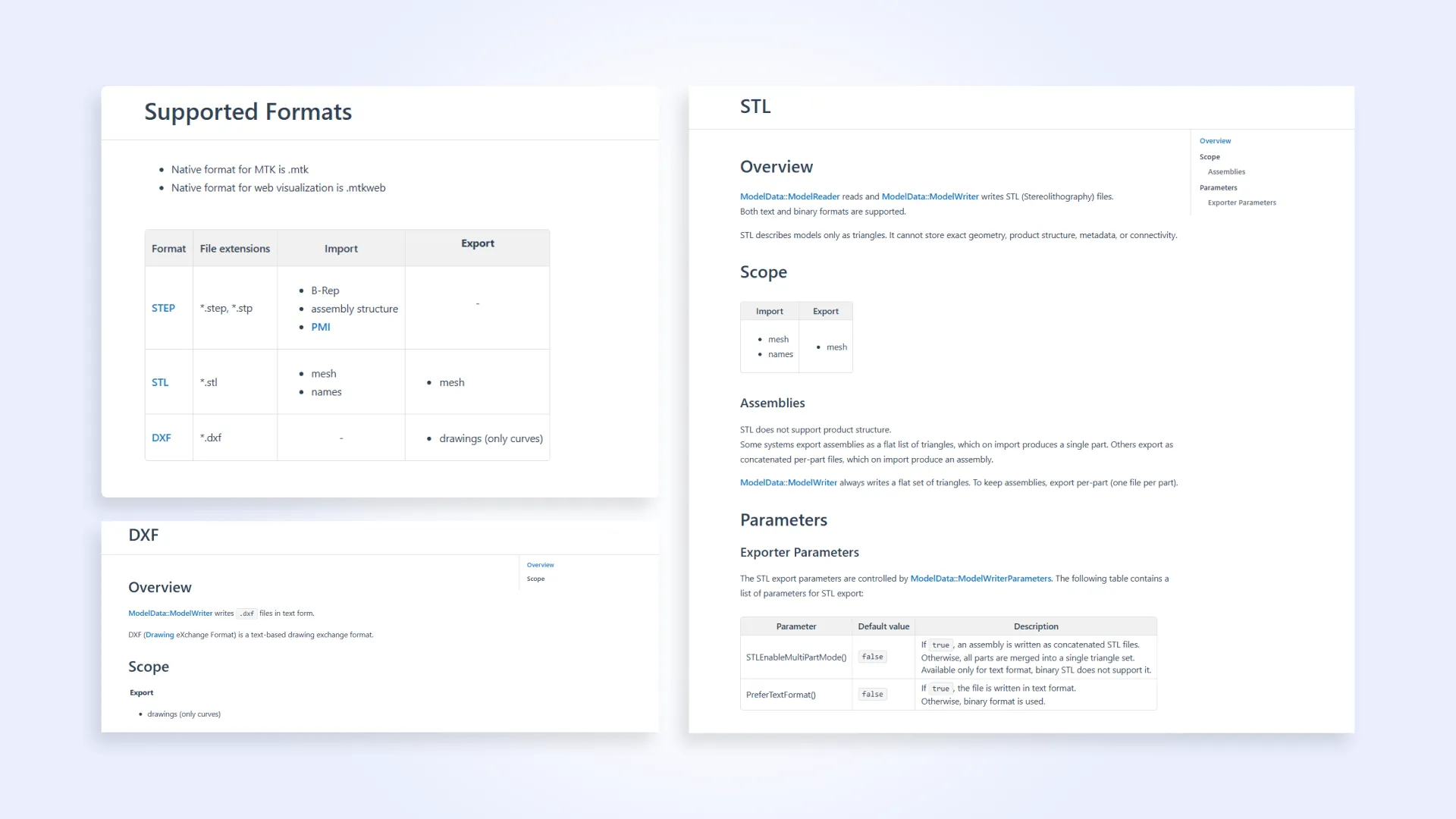

Enhanced API

We continue to evolve API for better consistency and maintainability. The new ModelData::ModelWriter class now serves as a new unified entry point for all supported export formats, such as the latest STL and DXF. Additionally, the MTK version is now automatically written to logs upon initialization, making debugging and support easier.

Sheet Metal

Forming feature recognition

We are glad to introduce a new class: SheetMetal_FormingFeature. It represents formed features, such as embosses, and provides access to key parameters like length, depth, and axis. This extends our ability to handle Sheet Metal processes more effectively.

Improved processing of non-Sheet metal models

This release focuses on increasing the stability of our recognition algorithms. A key enhancement ensures that models not intended for sheet metal operations—such as tube-like parts—no longer cause the application to crash. This improvement ensures a more stable and predictable workflow.

New DFM check for CNC Machining

MTK now reports minimum edge distances for threaded holes through a new DFM check: DFMMachining_SmallDistanceBetweenThreadedHoleAndEdgeIssue. This analysis helps you spot potential weaknesses early, saving time and cost by preventing this manufacturing issue before it happens.

Updated documentation

You can now read comprehensive new sections dedicated to working with STL and DXF formats, providing insights into their parameters, and check a new supported formats table.

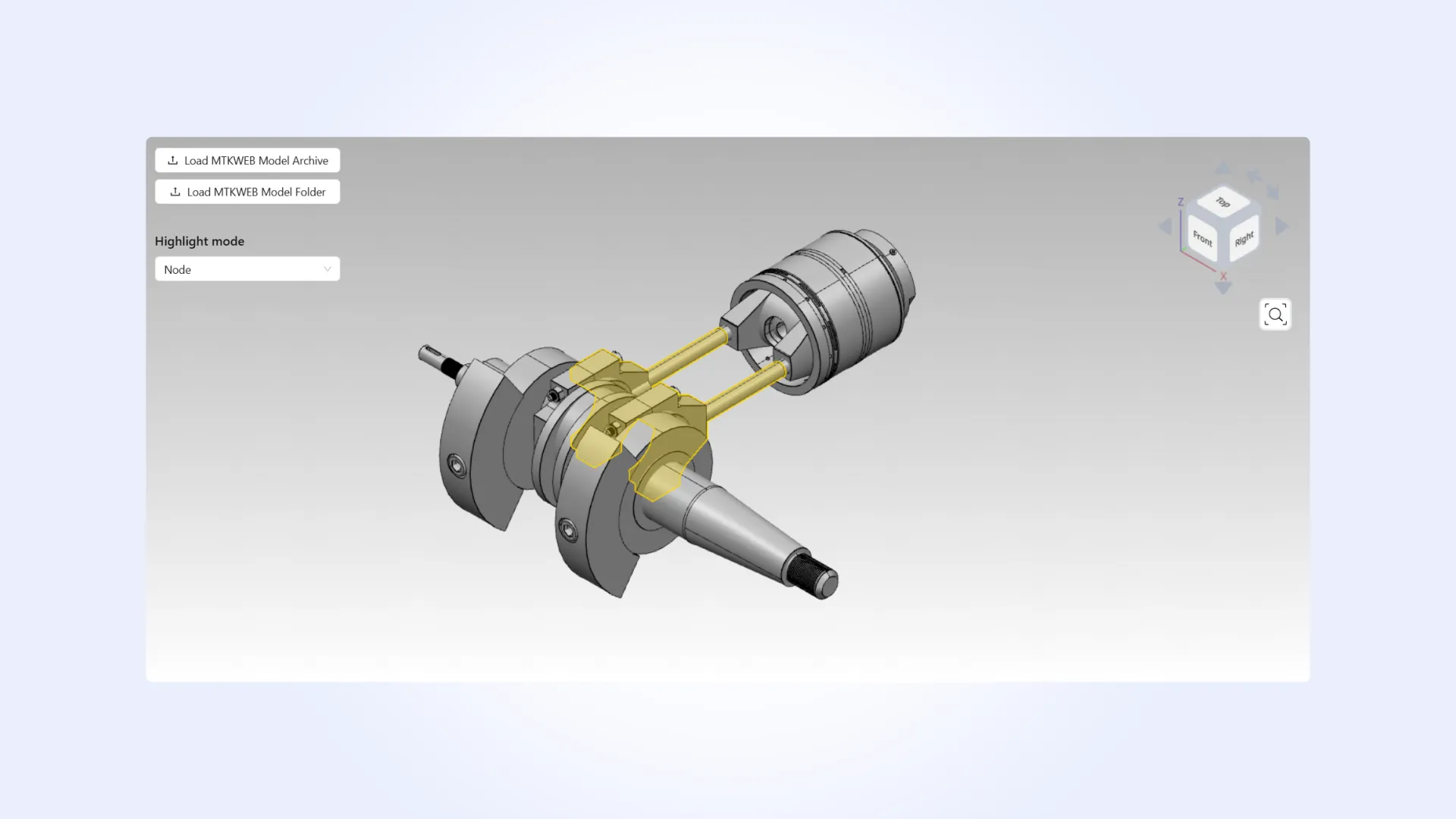

Improved MTK Web examples

We have upgraded the viewing experience in MTK Web examples. The new custom viewcube improves 3D navigation, while sheet metal unfoldings are now logically displayed in a 2D mode instead of 3D.

This release also includes a more attractive postprocessing-based highlighting effect and the option to highlight objects on mouse hover. Moreover, there are a few small fixes for measurements and camera control that creates a smoother, consistent user experience.

There are also some minor changes in Manufacturing Toolkit. To get the full list of the 2025.6 updates, read the CHANGES.txt file.