MTK Workbench initial release, PDF import, new DFM checks, and performance improvements in Manufacturing Toolkit 2025.7

Introducing MTK Workbench, a desktop application for analyzing MTK workflows. The release also brings new features and improvements, including PDF import for 2D curves, new DFM checks, an updated MTK Converter API, and visual enhancements in Web.

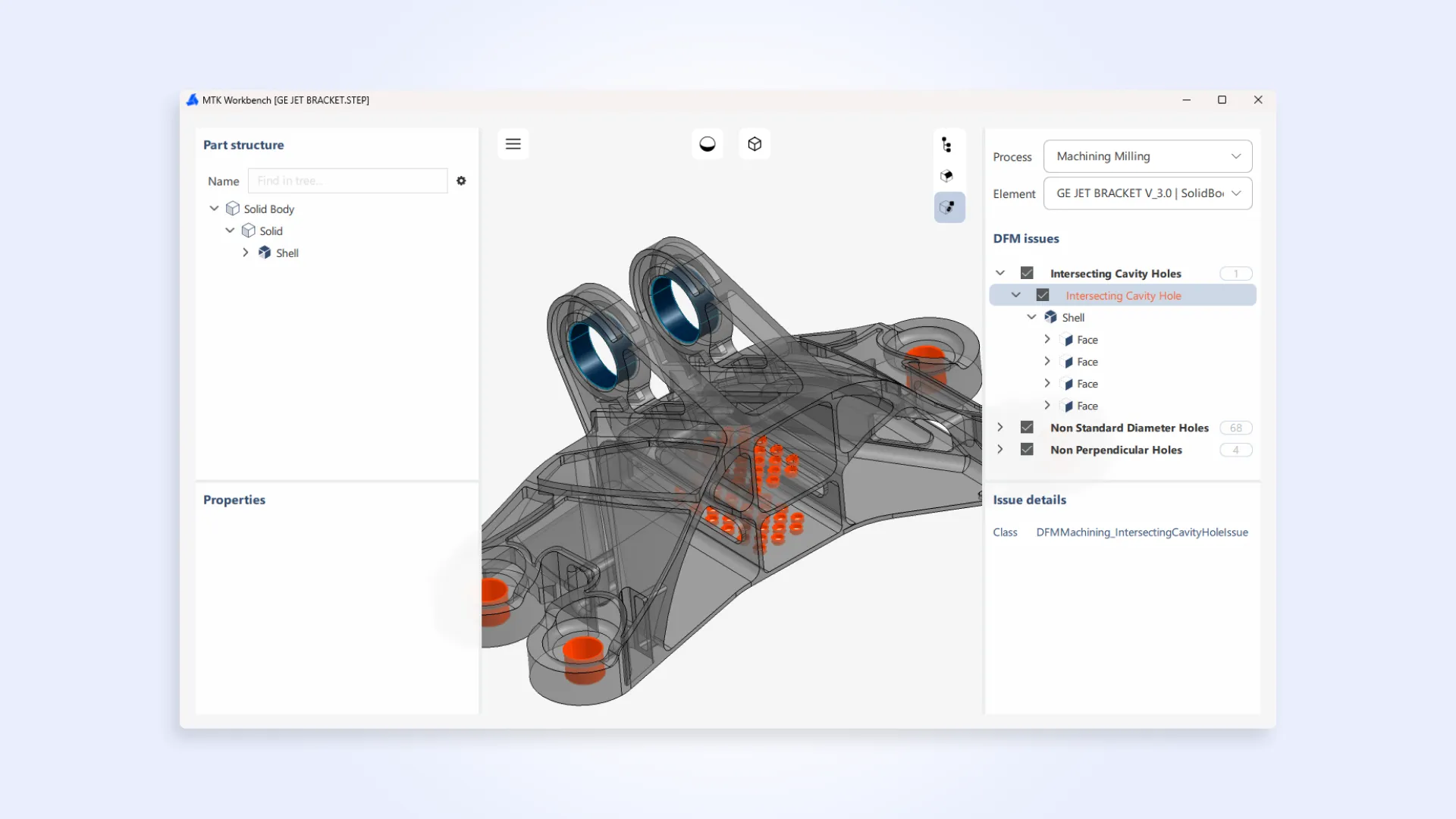

MTK Workbench initial release

We are excited to announce the initial release of MTK Workbench, a desktop application designed for viewing, testing, and deep analysis of MTK workflows before integrating MTK into your own application. It supports import and export of all MTK-compatible file formats and provides an integrated 3D/2D viewer with navigation tools, a model tree, and property inspection.

Core MTK capabilities such as Feature Recognition, DFM Analysis, Unfolding, and other workflow features are available directly within the Workbench. You can switch between wireframe and shaded visualization modes, and choose from multiple selection types, including solid, face, wire, edge, and vertex, for precise interaction with models.

Currently, Workbench supports CNC machining, sheet metal, and injection molding workflows, allowing you to inspect detected manufacturing features and review part properties. This enables interactive validation and refinement of models before workflow integration.

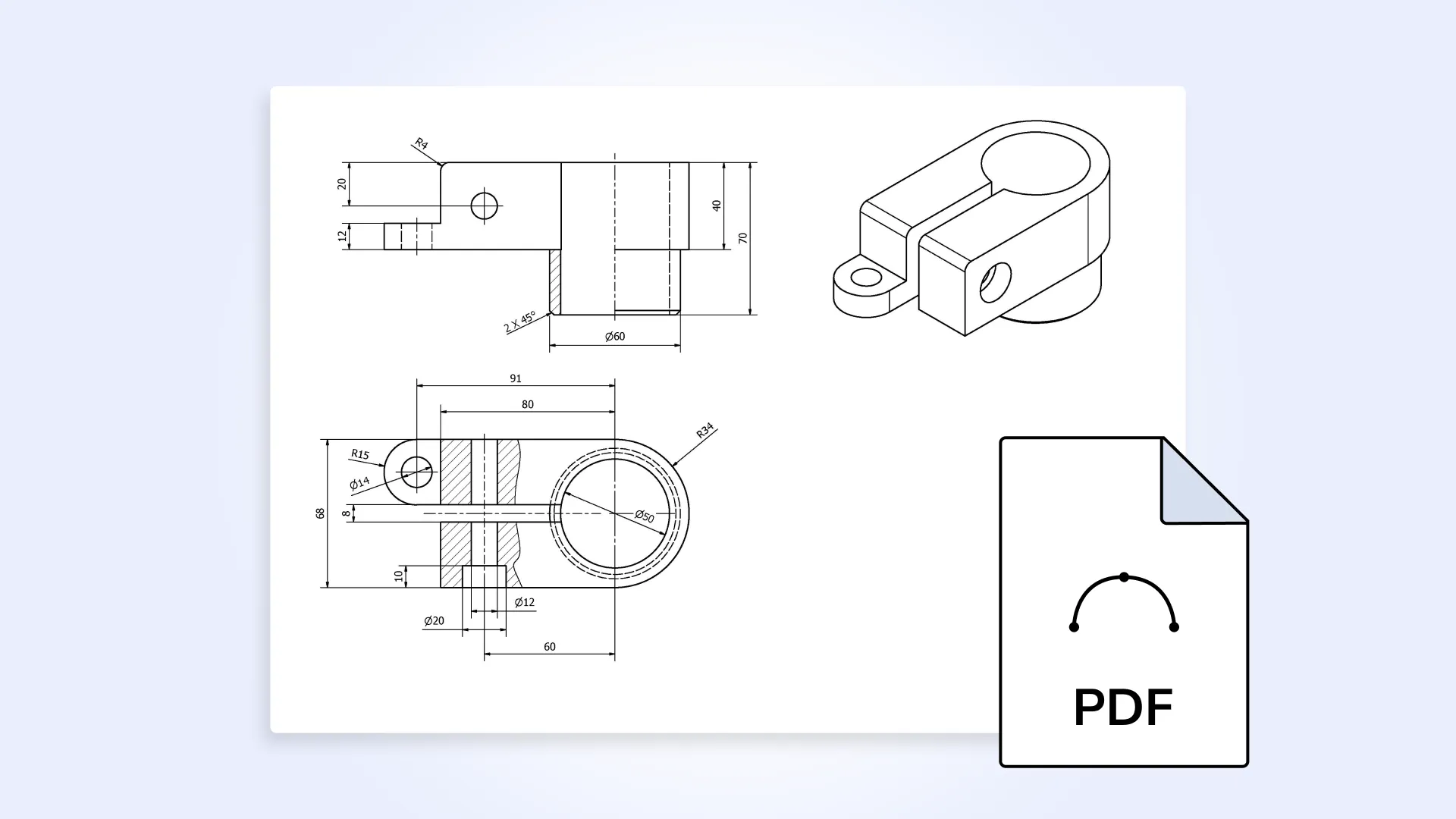

PDF import for 2D curves

The new MTK release expands support for working with 2D drawings. While the previous version introduced the ability to export 2D curves to DXF, you can now also import 2D curve geometry from PDF.

Although only contour curve geometry is supported at this stage, without additional 2D semantics, it already represents an important step toward automated extraction of structured information from 2D engineering drawings for precision manufacturing workflows.

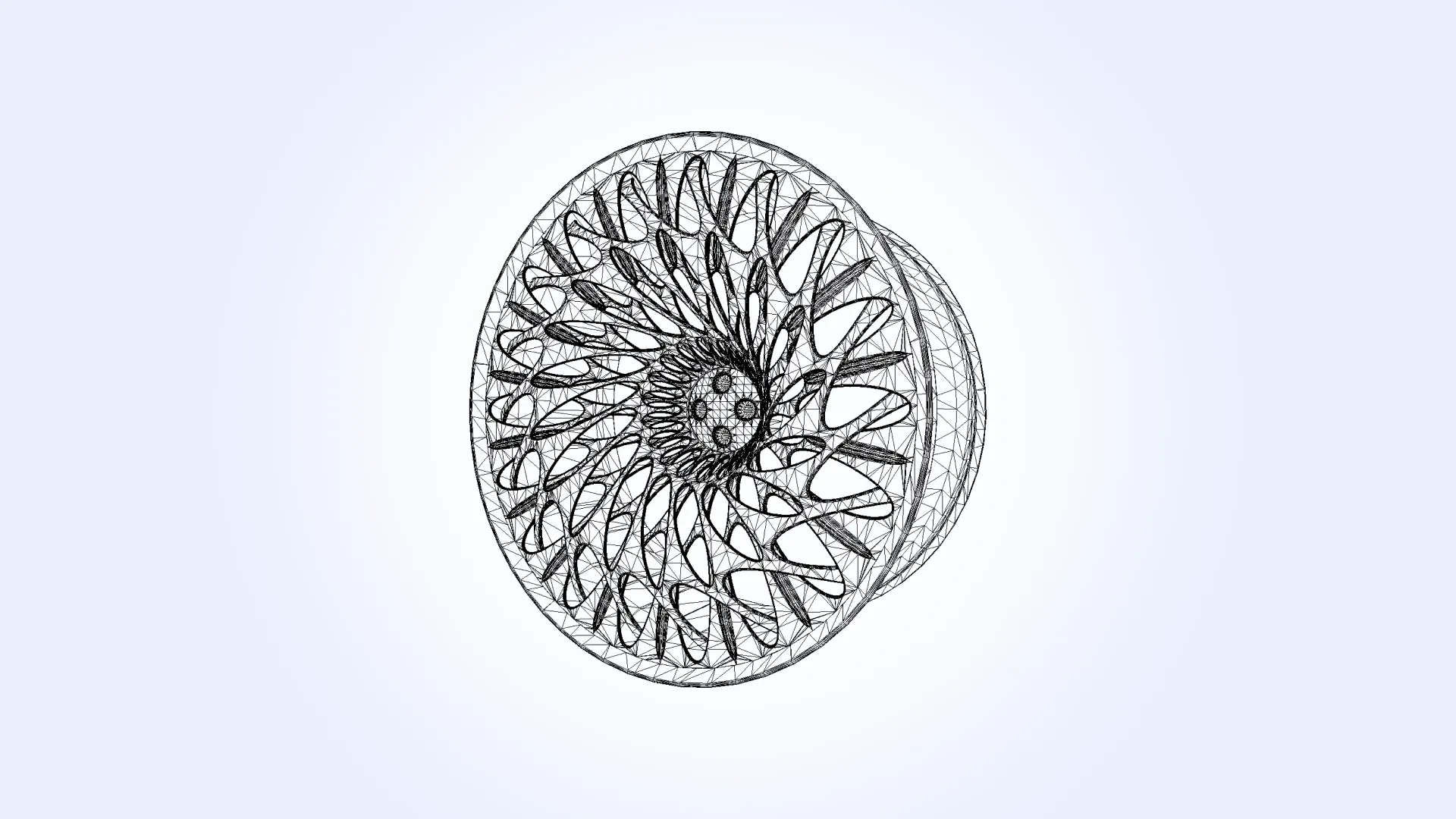

MeshBody import/export

In MTK 2025.4, we introduced the ModelAlgo::MeshGenerator class, which enables generation of triangulations for B-Rep shapes with user-defined granularity. You can generate meshes for all shapes or selectively for those that do not already have triangulation.

In MTK, polygonal geometry is represented by ModelData::MeshBody, which contains one or more ModelData::MeshShape elements. Starting with this release, you can export a MeshBody to the native .mtk format or, conversely, import it from an .mtk file. The generated mesh can be useful for basic computations or for visualization on your side.

Improved performance of CNC and wall thickness algorithms

To help your applications run even faster, we continue to improve algorithm performance. In this release, overall DFM and feature recognition performance for CNC machining has increased by approximately 40%, while wall thickness analysis algorithms have improved by about 35%.

MTK Converter updates

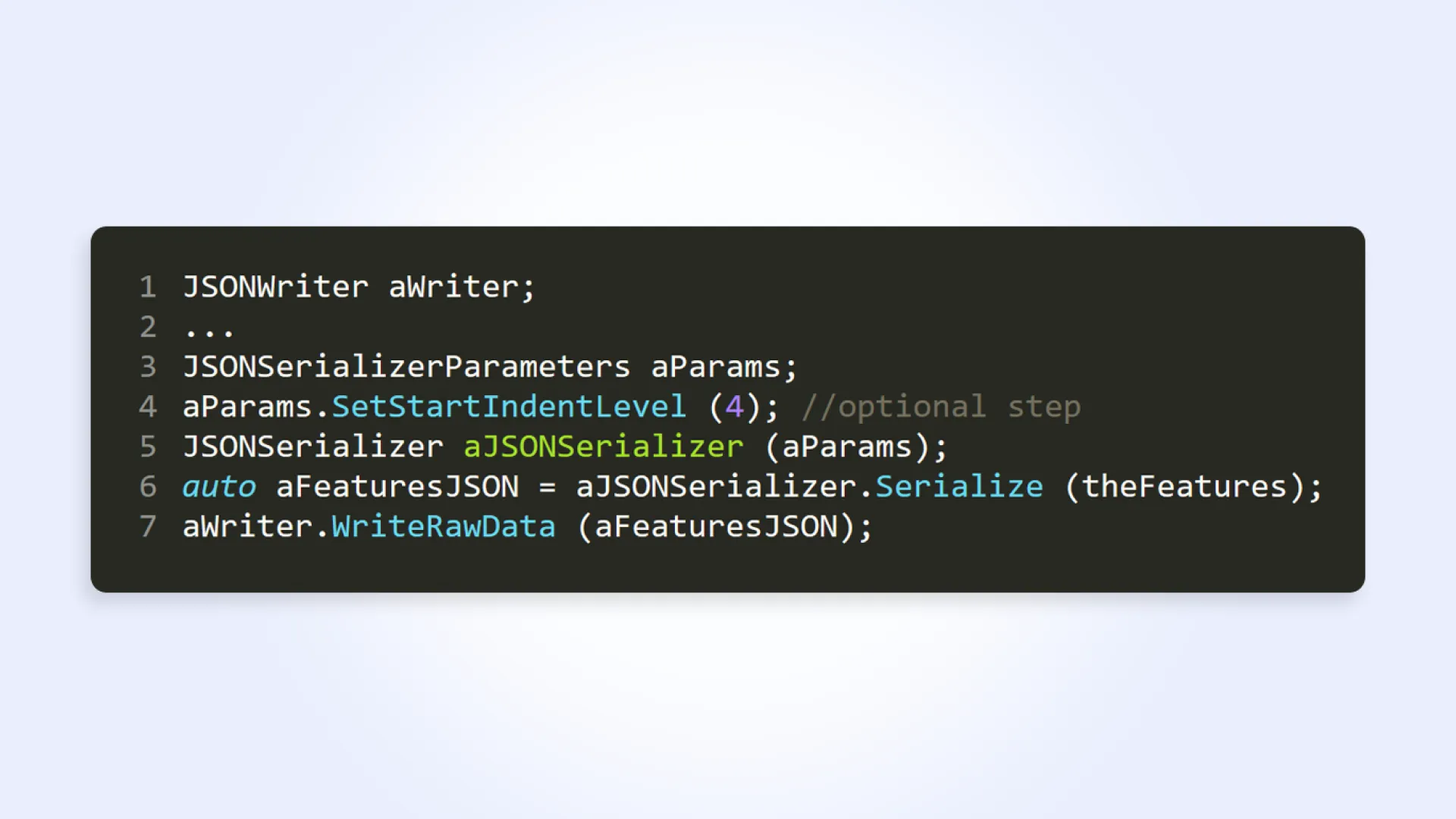

New API Utilities::JSONSerializer

MTK Converter is an executable CLI tool for Windows and Linux that helps integrate MTK data into web applications. It represents a pre-built version of MTK Converter Example and is used in Examples and Tutorials.

A new API, Utilities::JSONSerializer, is now available in MTK Converter. It simplifies the generation of JSON reports for features and DFM issues and significantly reduces the amount of required code. All examples now rely on the internal API, ensuring consistent behavior across all languages. Previously, results in the C#, Python, and Java wrappers could differ from C++, but this inconsistency has now been eliminated.

A public, open-source implementation of JSONSerializer is available under examples/helpers, allowing users to customize it.

Note: only the C++ implementation will be actively maintained and kept fully up to date. The open-source JSONSerializer implementations for wrappers will not be updated every release, but approximately every six months or less frequently due to the required effort.

Aggregated results for all bodies in multi-body parts

The logic for processing multi-body parts in MTK Converter has been updated. Previously, the web viewer displayed results for only one body within a part. To address this, the JSON file structure was revised so that data is now written for all bodies within a single part section.

As a result, the part section in the JSON file now contains processing results for all bodies, rather than just one. The corresponding examples for C++/C#/Java/Python have been updated accordingly.

New DFM checks

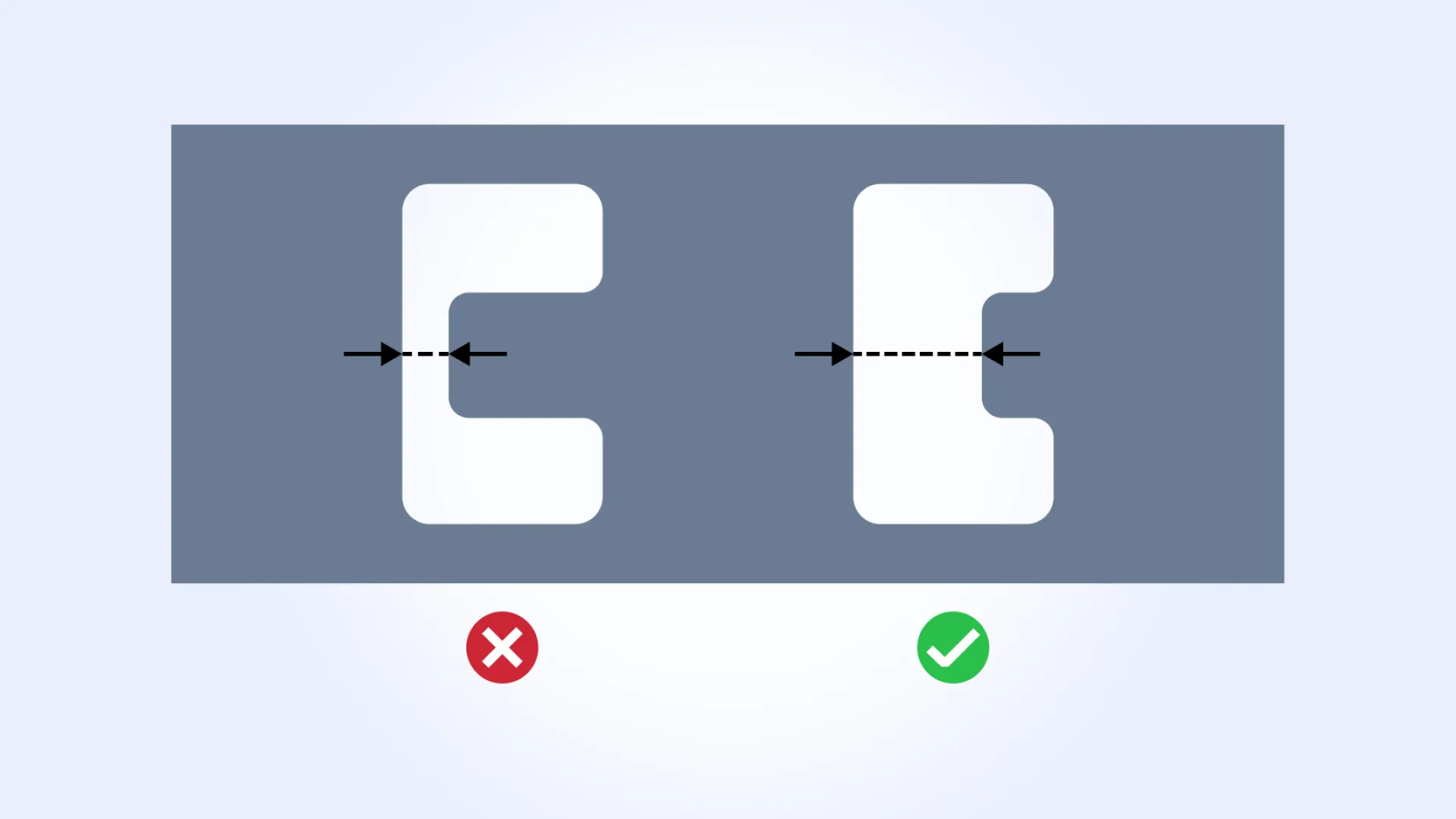

Narrow cutout issue (sheet metal)

In sheet metal, a new check DFMSheetMetal_NarrowCutoutIssue has been added. Cutouts narrower than the required width may result in incomplete cutting, slag accumulation, and dimensional inaccuracies.

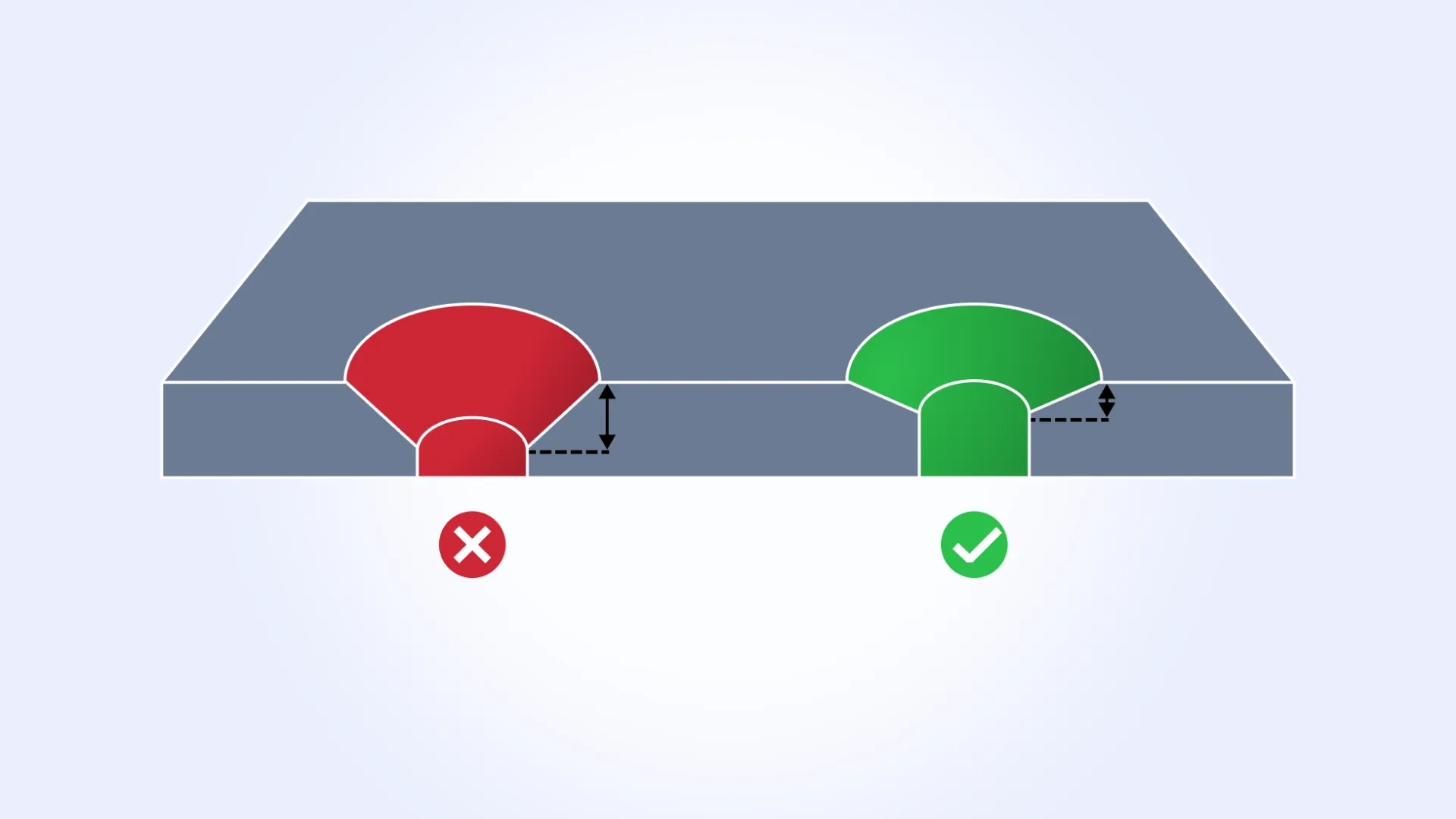

Excessive countersink depth issue (sheet metal)

Another sheet metal check, DFMSheetMetal_LargeDepthCountersinkIssue, is now available. Excessive countersink depth relative to sheet thickness can bulge the opposite face, degrade surface quality, and weaken the sheet area around the hole.

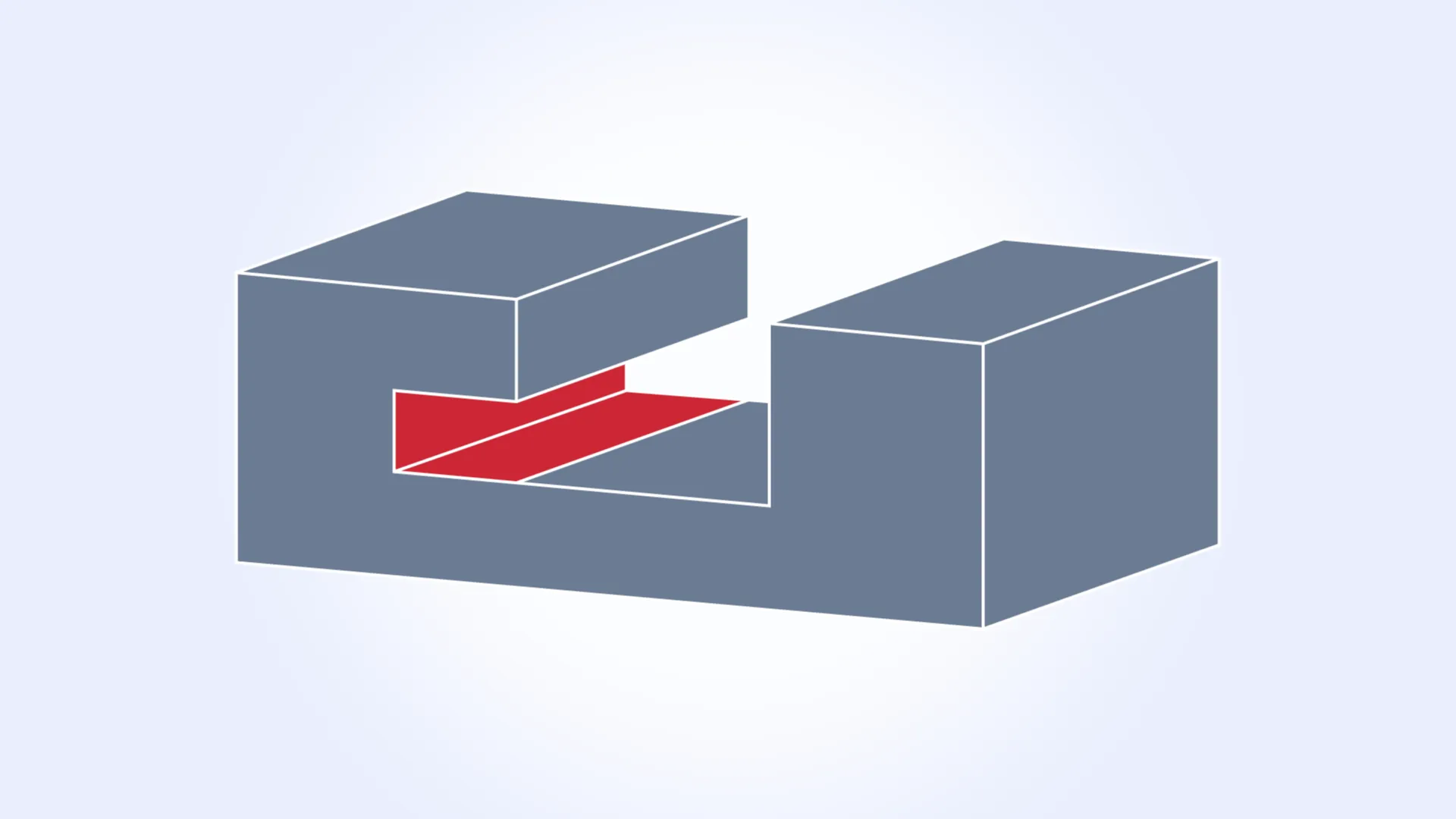

Undercuts unreachable by standard tools (CNC machining)

For CNC machining, a new check DFMMachining_UndercutIssue has been added. Recessed or overhanging regions can make some areas inaccessible to standard tooling, potentially requiring multi-axis machining, reorientation, or post-processing.

Drawing API and visual style updates in Web

In the new release, the Drawing API has been introduced, allowing you to import drawings from the .mtkweb format.

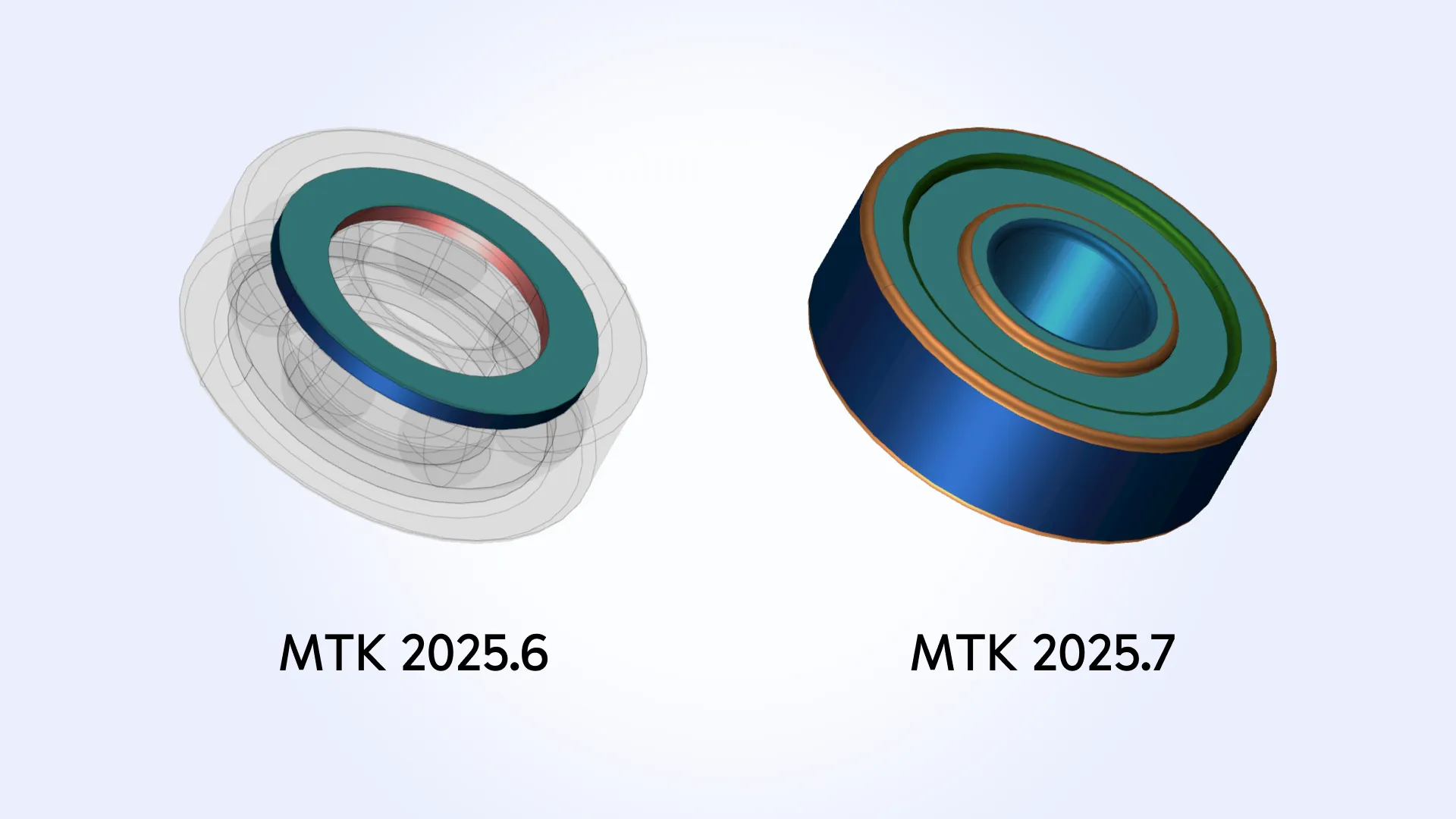

This update also brings multiple improvements to the 3D visual style in Web:

- Improved rendering of translucent materials and wireframe objects (e.g., B-Rep edges).

- Updated default lighting.

- A new default physical material for model rendering.

- Added model shadows (enabled by default).

There are also some minor changes in Manufacturing Toolkit. To get the full list of the 2025.7 updates, read the CHANGES.txt file.