New nesting functionality, updated sheet metal and CNC machining processes in Manufacturing Toolkit in release 3.24.7

Try a new nesting functionality, obtain accurate data during the unfolding sheet metal parts with embossing, and explore added typification for pockets in CNC machining.

The latest release of Manufacturing Toolkit 3.24.7 brings powerful new features and improvements to enhance your experience with processes. Let’s explore the highlights:

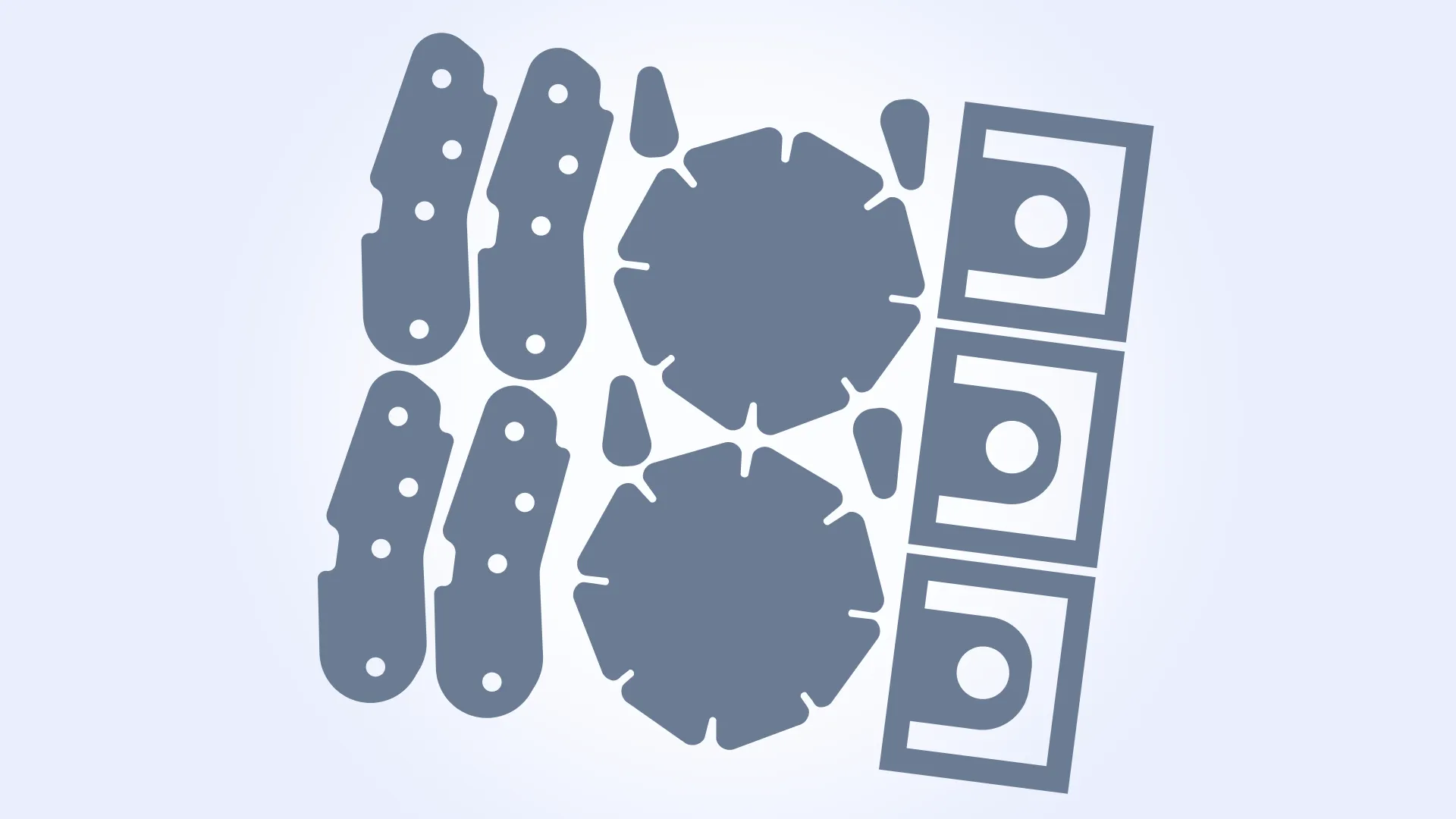

- Introduction of the 2D nesting functionality to optimize the placement of multiple freeform 2D shapes on a sheet;

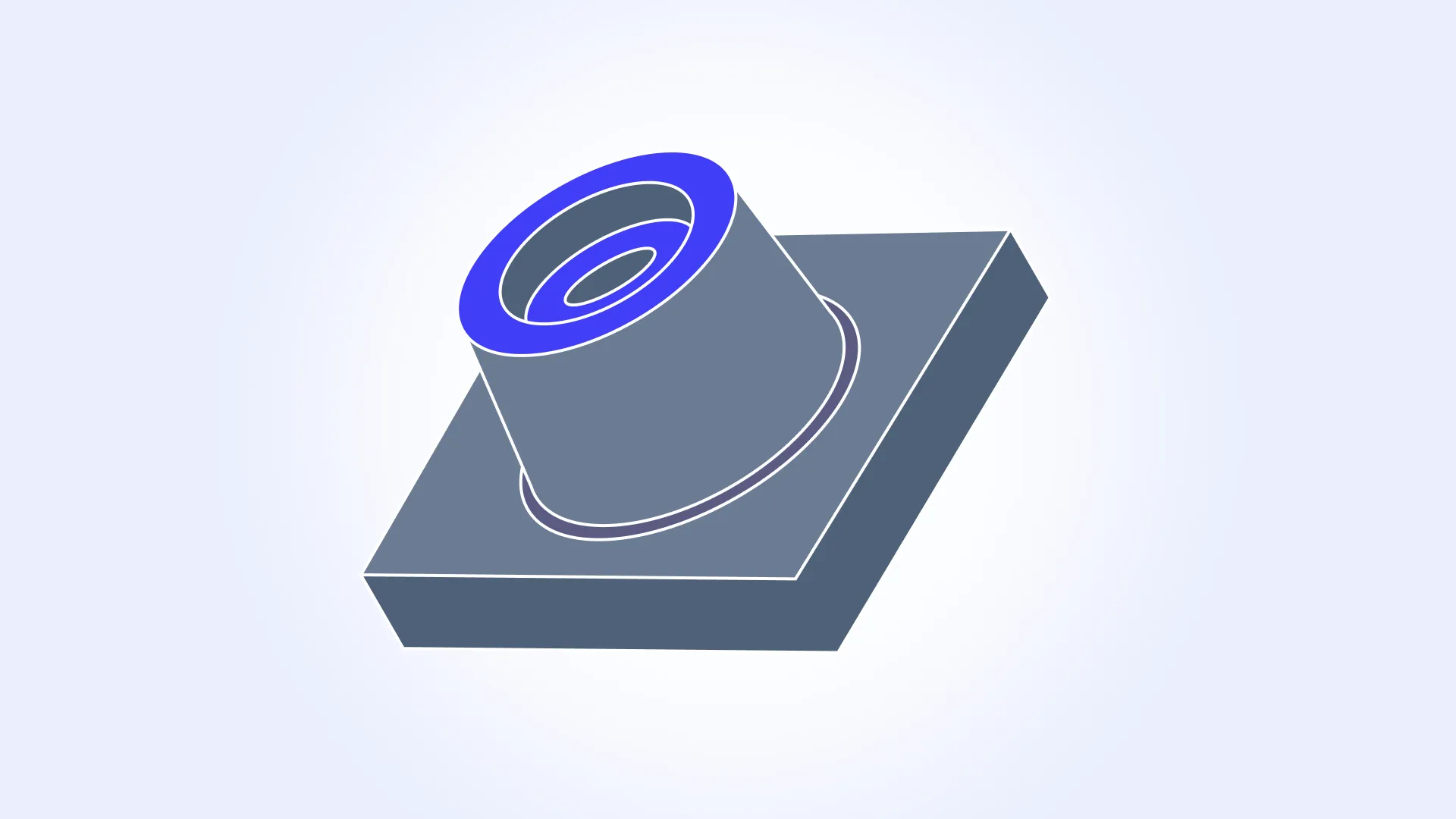

- Recognition of stepped holes and pocket types in CNC machining;

- Improvement of the unfolding process for sheet metal parts with embossing.

2D nesting introduction

We are excited to announce a completely new functionality in our latest release: 2D nesting. Now, you can optimize the placement of multiple freeform 2D shapes on a sheet, maximizing material usage and minimizing waste. To enable this, we’ve introduced a new drawing API to traverse and query 2D drawing data from the model.

The process starts from calculating layouts based on specified parameters and material properties. Once they are defined, our algorithm generates an optimal arrangement of patterns across the materials.

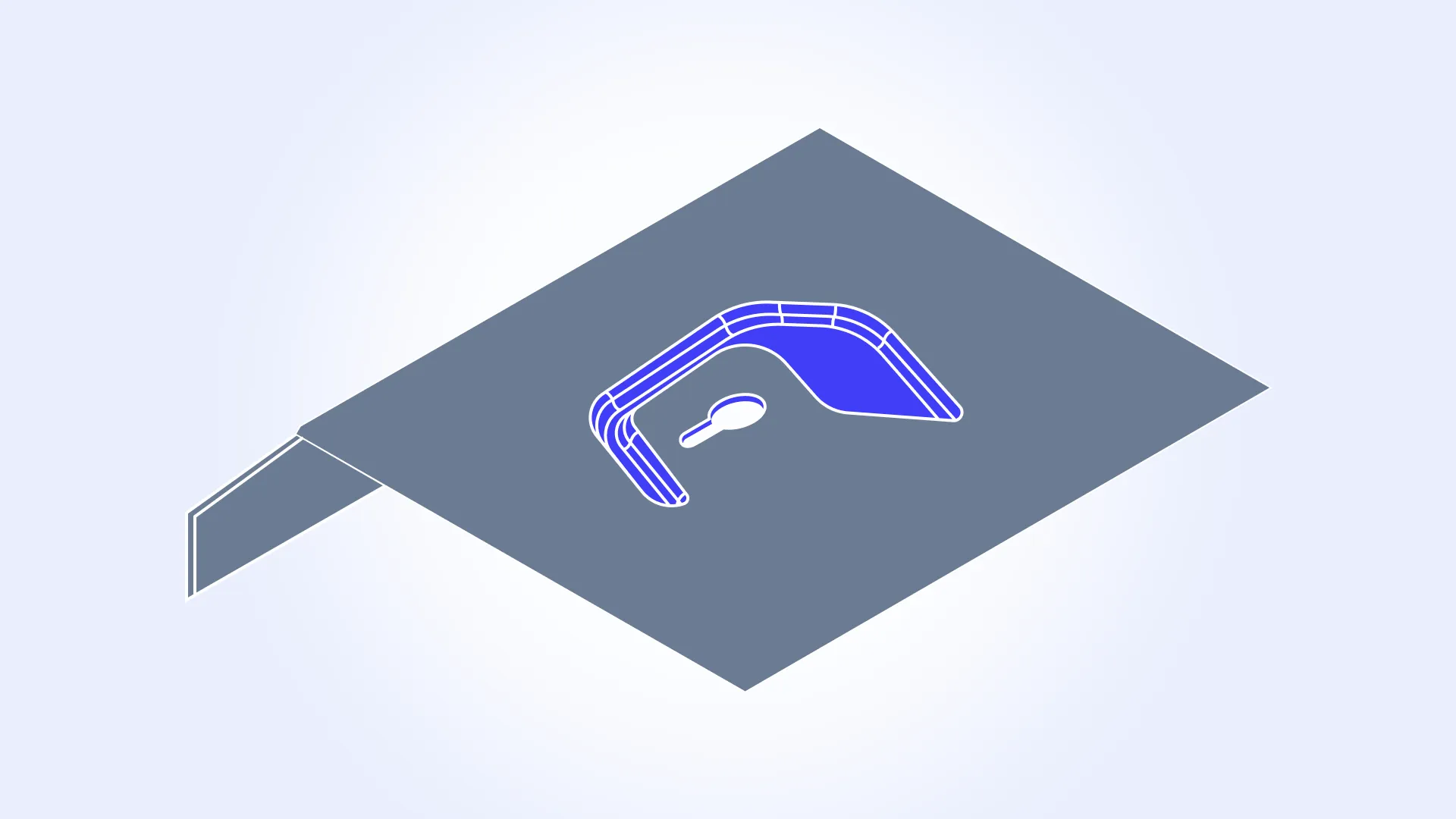

Improved unfolding sheet metal parts with embossing

Previously, sheet metal parts with embossing were not processed correctly, leading to inaccurate results during unfolding. To address this, we developed a dedicated algorithm to ensure that embossing is handled correctly. This improvement allows you to obtain accurate data during the unfolding process, significantly enhancing the reliability of sheet metal part processing.

We have also improved the processing of B-spline surfaces, allowing you to generate more precise flat patterns from intricate 3D shapes.

Recognition of new features and types in CNC machining

This time our main goal was to improve the recognition of holes and pockets. Previously, one stepped hole was recognized as separate features, but now it is considered as a single one with sub-features. Additionally, there is a new typification for pockets, which includes closed, open, and through types. We have also improved the recognition of holes, correcting cases where some of them were previously identified with the wrong type.

There are also some minor changes in Manufacturing Toolkit. To get the full list of the 3.24.7 updates, read the CHANGES.txt file.